The world of printing technology has evolved dramatically over the past few decades, introducing innovative methods that have transformed how we reproduce images, graphics, and text onto various materials. Among the most versatile and advanced printing technologies available today is sublimation printing. A sublimation printer allows users to produce vibrant, durable, and high-quality prints on a wide range of surfaces—from clothing and mugs to metal sheets and mobile covers. Whether you are an entrepreneur exploring printing for your business or an artist interested in custom designs, understanding how sublimation printers work and what makes them special is crucial.

This article explores every important aspect of sublimation printers, including their working principles, advantages, disadvantages, types, maintenance tips, and how to select the best model for your needs. By the end, you will have a clear understanding of how this technology operates and why it has become an essential tool for professional and personal printing.

1. Understanding Sublimation Printing

To understand what a sublimation printer does, you first need to know what sublimation printing means. Sublimation printing is a digital printing process that uses heat and pressure to transfer dye onto a material. The process involves turning solid dye particles directly into a gas without passing through the liquid stage. This unique transformation is known as sublimation, hence the name.

The Basic Principle

In simple terms, a sublimation printer prints an image onto a special type of paper called sublimation transfer paper using sublimation ink. Then, the printed paper is placed on the target substrate (such as a polyester T-shirt, mug, or metal plate) and exposed to high heat—typically around 350°F to 400°F (175°C to 205°C). When heated, the sublimation ink transforms into gas and penetrates the surface coating of the material. Once it cools, the ink solidifies and becomes part of the material, resulting in a vibrant, long-lasting print.

This is different from traditional inkjet or laser printing, where ink or toner simply sits on the surface. Sublimation printing chemically bonds with the material, making the print far more durable and resistant to fading or peeling.

2. Components of a Sublimation Printer

A sublimation printer is not drastically different in appearance from an ordinary inkjet printer, but its internal mechanism and ink system are uniquely designed to handle sublimation dyes. The key components include:

| Component | Function |

|---|---|

| Print Head | Transfers sublimation ink onto the sublimation paper. Precision in this part determines print clarity. |

| Ink Cartridge or Tank | Stores sublimation inks, typically in cyan, magenta, yellow, and black (CMYK). Some models may include extra colors for accuracy. |

| Sublimation Paper Feed System | Ensures smooth feeding of transfer paper during printing. |

| Heating Element (External) | Used in combination with the printer (e.g., heat press machine) to transfer designs to the substrate. |

| Control Panel and Software Interface | Allows users to adjust settings such as resolution, paper type, and print dimensions. |

These components work together to produce a consistent, high-resolution image suitable for heat transfer.

3. How Does a Sublimation Printer Work?

The sublimation printing process involves several steps that must be performed with precision to achieve high-quality results. Below is a breakdown of the process:

Step 1: Designing the Artwork

The process begins with creating a digital design on a computer using graphic design software like Adobe Illustrator, Photoshop, or CorelDRAW. The image is typically mirrored horizontally before printing, so that it appears correctly when transferred.

Step 2: Printing the Design

The design is printed onto sublimation transfer paper using the sublimation printer loaded with sublimation ink. The ink is specially formulated to vaporize under heat, unlike regular dye or pigment inks.

Step 3: Preparing the Substrate

The surface that will receive the print must be polyester-coated or made of polyester-based material. For hard surfaces like ceramics or metals, a polymer coating is applied to hold the sublimation dye.

Step 4: Heat Transfer

Using a heat press machine, the printed transfer paper is pressed against the substrate under high temperature and pressure. The typical temperature range is between 350°F to 400°F, and the time varies depending on the material (30–60 seconds for fabric, longer for ceramics).

Step 5: Cooling and Finishing

Once the heat press is removed, the substrate is allowed to cool. The ink that has turned into gas during heating solidifies and becomes a permanent part of the material. The result is a vibrant, long-lasting, and smooth print that does not crack or peel.

4. Types of Sublimation Printers

There are several types of sublimation printers designed for different applications and production scales. Understanding these types helps users choose the most suitable one for their needs.

| Type | Description | Best For |

|---|---|---|

| Desktop Sublimation Printer | Compact and affordable printers suitable for home or small business use. Common brands include Epson EcoTank and Sawgrass. | Small-scale printing, T-shirts, mugs, keychains |

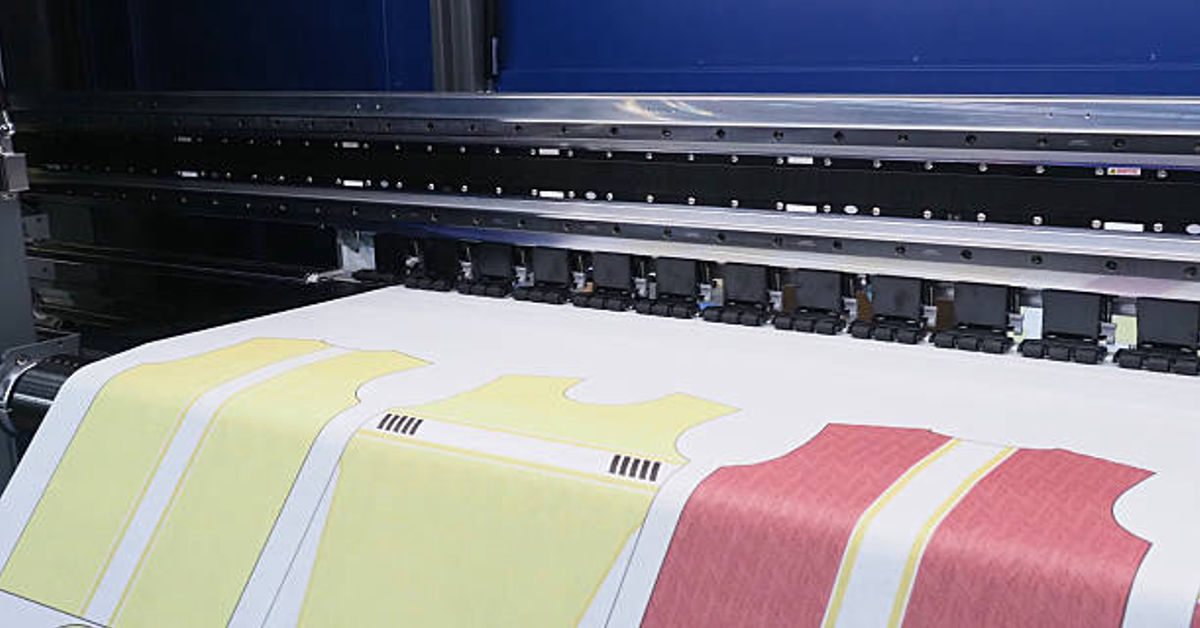

| Industrial Sublimation Printer | Large-format printers capable of handling rolls of fabric and continuous printing. They are used in commercial production. | Textile manufacturing, sportswear, banners |

| Photo Sublimation Printer | Specialized for high-resolution photo printing on photo paper or small items. | Photography studios, personalized gifts |

| Roll-to-Roll Sublimation Printer | Used for continuous fabric printing. It prints on sublimation paper rolls and transfers designs onto textile rolls using large heat presses. | Apparel production, flag and banner industries |

Each printer type has different speed, print width, and cost features, making it essential to select one based on your project requirements.

5. Advantages of Using a Sublimation Printer

Sublimation printing offers several advantages that make it stand out from other printing techniques like screen printing, inkjet, or heat transfer vinyl.

a. High-Quality and Vibrant Colors

Since the dye becomes part of the material, sublimation printing produces bright and vivid colors with photographic-quality resolution. The prints have smooth gradients, making them ideal for detailed designs and photographs.

b. Durability and Longevity

Unlike surface printing methods, sublimation prints do not crack, fade, or peel over time. The colors remain consistent even after repeated washing or exposure to sunlight.

c. Wide Range of Applications

Sublimation printers can print on various substrates, including clothing, mugs, tiles, mouse pads, keychains, and phone cases, as long as they are coated with a polyester surface.

d. Eco-Friendly Process

Sublimation printing produces minimal waste compared to screen printing, as it does not require excess ink or water. The process is cleaner and more efficient.

e. No Drying Time

Once the transfer is complete, the product is ready to use immediately—there is no need to wait for the ink to dry.

6. Limitations of Sublimation Printing

While sublimation printing has numerous benefits, it also has a few limitations that should be considered before investing in the equipment.

| Limitation | Explanation |

|---|---|

| Material Restriction | Sublimation works only on polyester fabrics or polymer-coated surfaces. It is not suitable for cotton or untreated materials. |

| Color Limitations | Works best on white or light-colored backgrounds since sublimation ink is translucent. |

| Initial Cost | The setup cost, including a printer, heat press, and consumables, can be relatively high. |

| Size Limitation | Desktop printers have limited printing areas; large-format printing requires industrial models. |

Despite these limitations, sublimation printing remains one of the most efficient and popular choices for customized merchandise.

7. Applications of Sublimation Printers

Sublimation printers are used in a wide variety of industries due to their versatility and ability to produce permanent prints. Below are the most common applications:

a. Textile and Apparel Industry

Sublimation is widely used for producing custom T-shirts, sportswear, jerseys, and uniforms. The method allows for full-color, edge-to-edge printing without affecting the fabric’s texture or breathability.

b. Home Décor

Designers use sublimation to print on curtains, cushions, tablecloths, and wall art. The vibrant prints add aesthetic value and last longer compared to surface-printed designs.

c. Promotional Products

Businesses often use sublimation printers to create branded items such as mugs, keychains, mousepads, and bags for marketing and promotional purposes.

d. Photography and Art

Sublimation photo printers are used to print high-resolution images on photo panels, plaques, and aluminum sheets, providing durable and professional-quality reproductions.

e. Signage and Banners

Large-format sublimation printers are used to produce banners, flags, and displays with bright colors that resist outdoor weather conditions.

8. Comparison: Sublimation vs. Other Printing Methods

The table below highlights the key differences between sublimation and other popular printing techniques.

| Feature | Sublimation Printing | Screen Printing | Heat Transfer Vinyl (HTV) |

|---|---|---|---|

| Durability | Excellent; becomes part of material | Moderate | Good but can peel over time |

| Color Vibrancy | High | Moderate | Limited by vinyl color |

| Material Type | Polyester or coated surfaces | Almost any fabric | Any fabric |

| Setup Cost | Moderate to High | High for large runs | Low |

| Production Speed | Fast for small runs | Slower setup but efficient for bulk | Slow for large designs |

| Design Complexity | Excellent for detailed graphics | Limited for complex images | Limited |

| Touch Feel | No raised texture | Slightly thick | Raised texture |

From the comparison, sublimation clearly excels in terms of image quality and durability, making it ideal for professional-grade applications.

9. Choosing the Right Sublimation Printer

Before purchasing a sublimation printer, consider the following factors:

a. Print Size and Volume

If you are running a small business or hobby shop, a desktop printer like the Epson EcoTank ET-15000 or Sawgrass SG500 may suffice. For industrial production, large-format printers like the Mimaki TS100 or Roland Texart are better options.

b. Ink System

Printers with continuous ink supply systems (CISS) are more cost-effective for high-volume printing, as they reduce cartridge replacement costs.

c. Resolution

For professional results, choose a printer with at least 1200 x 600 dpi print resolution. This ensures detailed and sharp images.

d. Connectivity

Ensure the printer supports modern connectivity options like Wi-Fi, USB, and Ethernet to facilitate easy operation and network printing.

e. Support and Software Compatibility

Look for printers with good technical support and compatibility with major design software programs.

10. Sublimation Inks and Papers

The quality of sublimation prints depends heavily on the type of ink and paper used.

Sublimation Ink

Sublimation inks are formulated with disperse dyes that convert to gas under heat. Good-quality inks ensure consistent color reproduction and prevent clogging of the print head.

| Color Set | Description |

|---|---|

| CMYK | Standard four-color set for general printing |

| Extended Gamut | Adds light cyan, light magenta, and gray for smoother tones and photo-quality output |

Sublimation Paper

Sublimation papers are coated to hold ink in place and release it efficiently during heat pressing. Using the correct paper for your printer and substrate ensures optimal color transfer.

11. Maintenance and Care Tips

Proper maintenance extends the life of your sublimation printer and ensures consistent print quality.

- Use the Printer Regularly: Printing frequently prevents ink from drying or clogging the nozzles.

- Clean the Print Heads: Run nozzle checks and cleaning cycles periodically.

- Use Original Inks: Generic or incompatible inks can damage the print system and produce poor-quality results.

- Store Paper Correctly: Keep sublimation paper in a cool, dry place to prevent moisture absorption.

- Perform Software Updates: Ensure printer firmware and drivers are up to date for better performance.

- Avoid Dust Exposure: Keep the printer covered when not in use to prevent dust accumulation on internal components.

12. Common Issues and Troubleshooting

| Issue | Possible Cause | Solution |

|---|---|---|

| Faded Colors | Incorrect heat or pressure settings | Adjust temperature/time according to substrate |

| Ghosting (Shadow Print) | Paper movement during heat pressing | Secure paper firmly with heat tape |

| Banding in Prints | Clogged nozzles or low ink | Run print head cleaning and check ink levels |

| Color Mismatch | Wrong ICC profile or ink brand | Calibrate printer with correct color profile |

| Paper Jams | Incorrect paper type or loading | Use recommended sublimation paper and load properly |

13. Environmental Impact of Sublimation Printing

Sublimation printing is often considered more sustainable compared to traditional printing methods because it produces minimal waste. There are no harmful solvents or excess water used in the process. Additionally, the prints are long-lasting, reducing the need for reprints. However, it is important to dispose of used transfer papers and empty ink containers responsibly to maintain eco-friendliness.

14. Cost Analysis and ROI

The cost of starting sublimation printing depends on the scale of operation. Here’s a general overview:

| Expense Category | Estimated Cost (USD) |

|---|---|

| Sublimation Printer (Desktop) | $300 – $700 |

| Heat Press Machine | $150 – $500 |

| Sublimation Paper (per 100 sheets) | $20 – $50 |

| Sublimation Ink Set | $50 – $100 |

| Blanks (T-shirts, mugs, etc.) | Variable |

The average return on investment (ROI) is quite high because customized items can be sold at a significant markup. A small-scale business can often recover initial investment within a few months if operated efficiently.

15. Future Trends in Sublimation Printing

With advancements in technology, sublimation printing continues to evolve rapidly. Some emerging trends include:

- Eco-Friendly Inks: Development of biodegradable inks to reduce environmental impact.

- Smart Printing Software: Automated color correction and image enhancement tools.

- Hybrid Printers: Machines capable of both sublimation and direct-to-film (DTF) printing.

- 3D Sublimation: Technology that allows full-wrap printing on irregular surfaces like phone cases and bottles.

These innovations are making sublimation printing more accessible, efficient, and sustainable.

Conclusion

A sublimation printer is more than just a printing machine—it’s a gateway to creativity, personalization, and business opportunities. Whether used for small-scale crafts or industrial applications, sublimation printing delivers exceptional quality, durability, and color brilliance that traditional methods can hardly match. Understanding the process, equipment, and materials involved ensures that every print you produce meets the highest standards of quality and professionalism.

From T-shirts and mugs to décor and signage, sublimation technology continues to redefine how we bring digital designs to life in the physical world. With proper care, knowledge, and creativity, a sublimation printer can be one of the most rewarding investments for both businesses and enthusiasts alike.

Frequently Asked Questions (FAQs)

1. What materials can be used for sublimation printing?

Sublimation works best on polyester fabrics or polymer-coated surfaces like mugs, metal sheets, and keychains. It cannot print directly on cotton or untreated materials.

2. Can I use regular ink in a sublimation printer?

No. Regular inkjet inks cannot sublimate. You must use specially formulated sublimation ink that vaporizes under heat to bond with the substrate.

3. How long do sublimation prints last?

When properly applied, sublimation prints can last for several years without fading, even after multiple washes or sun exposure.

4. Is sublimation printing profitable?

Yes. Because of the growing demand for customized products, sublimation printing can be a highly profitable business with low production costs and high return margins.

5. Can sublimation be done on dark fabrics?

Sublimation works best on white or light-colored backgrounds since the inks are transparent. For dark fabrics, an alternative method such as heat transfer vinyl (HTV) or direct-to-film (DTF) printing is recommended.